So you’ve got a fresh design ready to go, maybe for a tee, a hoodie, a farm of custom merch for your squad, or for your brand’s next drop. You’re using DTF transfers (direct-to-film) because they’re clean, vibrant and pretty much the go-to for custom apparel right now. But here’s a critical tip: the fabric you print on matters a LOT. Even the best design can flake out, crack or fade if the fabric doesn’t ‘play nice’.

In this guide we’re going deep: I’ll walk you through what fabrics rock, which ones you should use with caution (or skip), how to test & pick the right ones, and how to treat your printed gear so it lasts. Everything will be explained in straightforward, human-friendly language (without too much jargon), but still packed with enough technical detail that you’ll know your stuff. Let’s go.

Why Picking the Right Fabric for DTF Transfers Is a Big Deal

Before we dive fabric by fabric, let’s zoom out and see why fabric compatibility matters so much for DTF printing.

- The DTF process: You print your design onto a special film, apply adhesive powder, then use a heat press to transfer it onto the garment. For that to work well, the design + adhesive needs to bond to the fabric’s surface and fibres.

- If the fabric’s too weird (too fuzzy, too stiff, too heat-sensitive, too stretchy) then that bond is weak- you end up with cracks, peeling, weird texture, faded colours.

- A good fabric makes the print look premium, vibrant and durable. A bad one makes it look cheap after one wash.

- Since your audience (teenagers, young adults) will wear these garments, not just hang them, you want them to survive the cycle: wear- washes- wear again.

In short: pick smart at the beginning, so your print not only looks good, but stays good. A good fabric ensures better ink adhesion and durability, prevents cracking or fading after washing, and maintains vibrant colour tones.

What to Check Before You Buy/Print (Fabric Checklist)

Here are the features you want to check before you press the print button:

- Fiber Composition

- Natural fibres (like 100% cotton) absorb ink/adhesive well and generally give good results.

- Synthetics (like polyester, nylon) can be good but require specific settings because of heat and surface issues.

- Blends (cotton + poly, tri-blends) are a hybrid, good comfort + durability if chosen correctly.

- Surface Texture & Smoothness

- Smooth and even surfaces allow the adhesive powder and film to grip properly.

- Rough textures, heavy weave, big texture patterns can interfere. For example, one guide says: “fabrics with smooth and even textures yield better results”.

- Color & Fabric Base

- Light colours allow the design to pop easier; dark fabrics often need an under-white layer or extra powder for opacity.

- The fabric colour won’t change the physical bonding issue, but the visual outcome is impacted.

- Heat Tolerance / Shrink Behavior

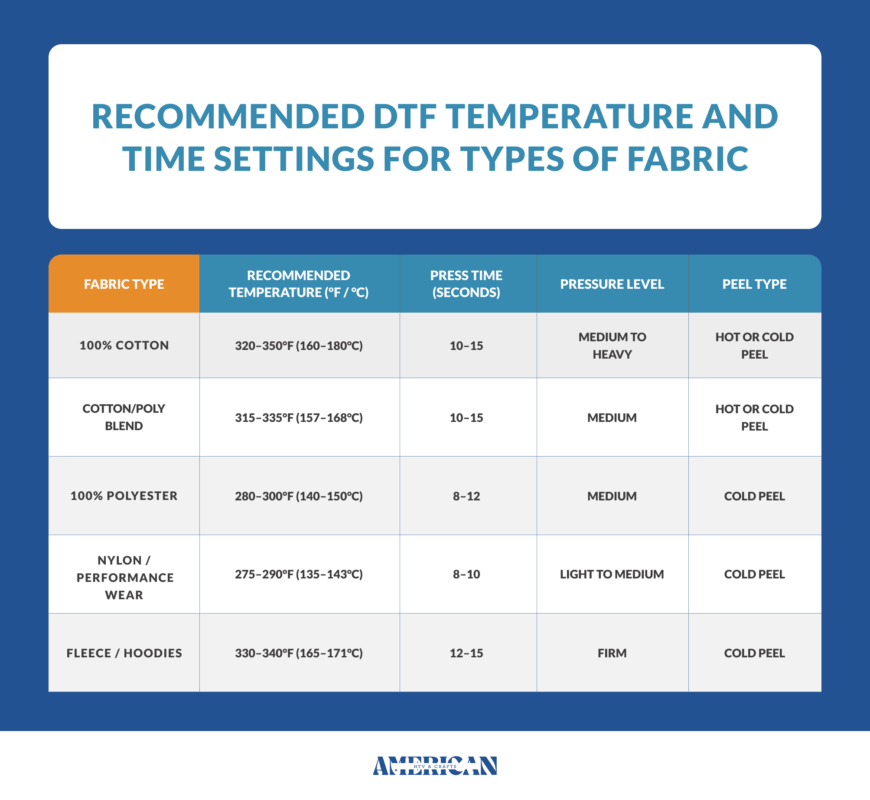

- Since DTF uses heat-pressing, the fabric must withstand the defined temperature, pressure and time without shrinking, melting or warping.

- If it shrinks after pressing, the design can distort. One source flags: “the heat resistance and adhesion properties matter”.

- Stretch & Recovery / Movement

- Fabrics that stretch a lot (high spandex/lycra content) can make the print crack when worn or washed.

- The print needs to flex a little with the fabric or be on a fabric that doesn’t stretch too wildly.

- Care & Durability Requirements

- How you’ll wash, wear and treat the garment matters. Even perfect prints on perfect fabric will fail if you wash badly. We’ll cover care later.

- The fabric’s long-term behaviour (does it pill, fade, shrink) impacts the look of the print.

When you check all these boxes, you’re putting yourself in the “likely to succeed” zone rather than “hope it works” zone.

Fabrics That Are Solid Choices for DTF Transfers

1. 100% Cotton

Why it works:

- Cotton absorbs ink and adhesive well- good bonds and vivid print. One guide says: “Cotton offers excellent ink absorption and detail clarity.”

- It’s comfortable, breathable, cool to wear- important for younger audiences.

- Very common in casual custom tees, hoodies.

Tips & caveats:

- Choose pre-shrunken cotton when possible, or at least fabrics that have minimal shrink. Because if the fabric shrinks after printing, you’ll risk print distortion. One source mentions shrinkage as a con for cotton.

- Pay attention to your heat press settings: cotton can take typical settings, but you don’t want to go overboard.

- On dark 100% cotton, you may still need white underbase or extra adhesive/powder to allow colours to pop.

Best for: Standard graphic tees, merch drops, everyday wear.

2. 100% Polyester

- Polyester may surprise you: “Polyester prints are bright and vivid… widely used in sportswear” according to several sources.

- It resists shrinking, retains shape, handles active wear, and the smooth finish can help prints look sharp.

- Good for hoodies, sports-style gear, custom gear with movement.

- Because it’s synthetic, you may need to lower your heat/pressure/time a bit compared to cotton. One guide states specific settings differ. Ensure the polyester is a smooth finish, not heavily textured or coated (coating can block adhesion).

- The “hand feel” (how it feels) of the print on polyester might differ (may feel less soft than cotton prints) — but good DTF films can close the gap.

3. Cotton-Polyester Blends (50/50 etc)

Why they’re a smart middle ground:

- Combine the comfort of cotton + durability of poly.

- Many custom clothing lines and merch runs favour blends because they minimise shrink, offer good print characteristics and cost less than specialty fabrics.

- Guides say: “blended fabrics offer the best of both worlds… DTF prints adhere well”.

Tips & caveats:

- Always check the blend ratio: something like 60% poly / 40% cotton might behave differently than 50/50.

- With blends, you still want to test one piece to confirm settings (heat/pressure/time) because the poly portion might react differently.

- For mass-merch, these are often the safe bet: a bit better durability than pure cotton, good cost efficiency.

Best for: Brand merch, groups, casual wear where you’ll print many pieces but still want decent quality.

4. Tri-Blends (Cotton / Polyester / Rayon)

Why you might pick it:

- Tri-blends are very popular for boutique style, “soft touch” tees. They drape well, feel lightweight, ideal for trend-following teens.

- One article says: “Tri-blends offer a unique texture and feel while still maintaining good printability.”

Tips & caveats:

- Because of the rayon (and extra fibres), the adhesive and print bonding may be slightly trickier. Some adhesion issues or durability differences may show. One source warns “rayon content can sometimes affect adhesion and durability.”

- Definitely test: stretch, wash, wear. Make sure the print holds up.

- For premium drops, this is a nice fabric, but it might cost more or require more care.

Best for: Boutique tees, fashion-y merch, limited edition drops where you want a premium feel.

5. Nylon (With Proper Treatment)

Why you’d go here:

- If you’re customizing outerwear, bags, backpacks or something non-tee, nylon is useful: lightweight, durable, smooth surface. Some DTF guides list it.

Tips & caveats:

- Nylon (especially if coated or used in outdoor gear) may not behave like cotton or poly: heat sensitivity, bonding issues, melting if settings are too hot.

- You’ll often need specific treatment: pre-pressing, correct adhesive powder, cold peel vs hot peel, lower temperatures.

- Because it’s less common for basic apparel prints, you might want to limit quantities or test small batches first.

Best for: Outerwear, accessories, backpacks, custom gear beyond just tees.

Fabrics to Use With Caution or Avoid for DTF

Even though DTF technology has come a long way and is more flexible than older print methods, there are fabrics that cause more trouble and are better avoided unless you’re experienced or testing heavily.

Here are fabrics you should proceed very cautiously with:

- Silk & Satin,slippery surfaces, delicate fibres, heat sensitivity. One source lists silk as one to be careful with.

- 100% Rayon- although soft and great feeling, the fibre can warp under heat and affect adhesion. Many guides mark it as risky.

- Heavily Textured Fabrics (e.g., corduroy, heavy wool, velvet), print might look uneven because the surface isn’t smooth.

- Water-proof or Coated Fabrics, the coating may repel ink/adhesive or heat may damage. One article states that coated fabrics block adhesion.

- High Stretch (High Spandex/Lycra Blends), if the fabric stretches a lot, the design may crack or distort when worn/washing.

- Leather / Suede (without proper treatment), some DTF articles say leather can work if treated, but it’s not straightforward.

Bottom line: If you’re just starting or doing a typical custom tee run, stick to the fabrics we listed earlier (cotton, poly, blends). Once you’re comfortable and have tested your process, you can explore the ‘caution zone’.

Care & Durability: How to Make Your Print Last

Printed Garment Care Checklist

- Turn it inside out before tossing in the wash- this minimises abrasion on the print.

- Wash in cold water, gentle cycle. Hot water can break down adhesive, fade colours, shrink fabric.

- Use a mild detergent, no bleach or harsh fabric softeners around the design area.

- Air-dry or tumble low. High heat in the dryer can damage both the fabric and the transferred film.

- When ironing, avoid direct contact with the printed area. Either iron inside out or use a cloth barrier between print and iron.

- If you’re doing a new print run: after pressing, allow the garment to cure (let the adhesive settle) before first wash or first wear.

- Store your printed garments properly- don’t fold heavily across the print for extended time, or hang where the print gets direct sun for long periods.

You’ll find that many custom printing guides emphasise these steps.

Real-World Scenario: How to Choose Fabric for Your Next Drop

Let’s put this into action with an example. Say you’re planning a custom tee drop for your brand, aimed at teens and young adults, for summer. You want something that looks good, feels comfortable, and stays fresh after multiple wears.

Here’s how you might think through the fabric choice:

- Goal: Casual, everyday wear tee, graphic design, vibrant colours.

- Audience: Teens/young adults who wash frequently, wear it to class, hang out in it, expect decent durability.

- Decision: 100% cotton or a 50/50 cotton-poly blend.

- If budget matters and you want max comfort- 100% cotton (pre‐shrunk).

- If you want longer durability, less shrink, fewer rejects- choose the 50/50 blend.

- Settings/Process: Use DTF film + powder, press with appropriate settings for that fabric (verify with supplier). After printing, allow proper cure, sample wash test.

- Care Instructions: Include care instructions with the garment (turn inside out, cold wash, air dry/low heat). This can help your customers take better care and keep your gear looking premium.

- Avoid: It would not make sense (for this drop) to pick tri-blend (premium cost) or nylon (outerwear) or a high stretch fabric that’s misaligned with the goal.

By thinking this way, you align the fabric, print method, audience and care instructions.

FAQs

Can I use DTF on dark fabrics?

What about very cheap shirts/blanks?

How many washes can a DTF print on a good fabric survive?

Does fabric weight matter?

Even within cotton, are there differences?

Absolutely. Ring-spun cotton, combed cotton, single-jersey vs interlock knit, all impact surface smoothness, print clarity and hand-feel. A Reddit user in the screen-printing community noted:

“In my experience, ringspun cotton like the Next Level 3600 can actually handle DTF pretty well if you cure and press it correctly.”

So yes, the quality of cotton matters.

So you’ve got a fresh design ready to go, maybe for a tee, a hoodie, a farm of custom merch for your squad, or for your brand’s next drop. You’re using DTF transfers (direct-to-film) because they’re clean, vibrant and pretty much the go-to for custom apparel right now. But here’s a critical tip: the fabric you print on matters a LOT. Even the best design can flake out, crack or fade if the fabric doesn’t ‘play nice’.

In this guide we’re going deep: I’ll walk you through what fabrics rock, which ones you should use with caution (or skip), how to test & pick the right ones, and how to treat your printed gear so it lasts. Everything will be explained in straightforward, human-friendly language (without too much jargon), but still packed with enough technical detail that you’ll know your stuff. Let’s go.

Why Picking the Right Fabric for DTF Transfers Is a Big Deal

Why Picking the Right Fabric for DTF Transfers Is a Big Deal

Before we dive fabric by fabric, let’s zoom out and see why fabric compatibility matters so much for DTF printing.

- The DTF process: You print your design onto a special film, apply adhesive powder, then use a heat press to transfer it onto the garment. For that to work well, the design + adhesive needs to bond to the fabric’s surface and fibres.

- If the fabric’s too weird (too fuzzy, too stiff, too heat-sensitive, too stretchy) then that bond is weak- you end up with cracks, peeling, weird texture, faded colours.

- A good fabric makes the print look premium, vibrant and durable. A bad one makes it look cheap after one wash.

- Since your audience (teenagers, young adults) will wear these garments, not just hang them, you want them to survive the cycle: wear- washes- wear again.

In short: pick smart at the beginning, so your print not only looks good, but stays good. A good fabric ensures better ink adhesion and durability, prevents cracking or fading after washing, and maintains vibrant colour tones.

Before we dive fabric by fabric, let’s zoom out and see why fabric compatibility matters so much for DTF printing.

- The DTF process: You print your design onto a special film, apply adhesive powder, then use a heat press to transfer it onto the garment. For that to work well, the design + adhesive needs to bond to the fabric’s surface and fibres.

- If the fabric’s too weird (too fuzzy, too stiff, too heat-sensitive, too stretchy) then that bond is weak- you end up with cracks, peeling, weird texture, faded colours.

- A good fabric makes the print look premium, vibrant and durable. A bad one makes it look cheap after one wash.

- Since your audience (teenagers, young adults) will wear these garments, not just hang them, you want them to survive the cycle: wear- washes- wear again.

In short: pick smart at the beginning, so your print not only looks good, but stays good. A good fabric ensures better ink adhesion and durability, prevents cracking or fading after washing, and maintains vibrant colour tones.

What to Check Before You Buy/Print (Fabric Checklist)

What to Check Before You Buy/Print (Fabric Checklist)

Here are the features you want to check before you press the print button:

- Fiber Composition

- Natural fibres (like 100% cotton) absorb ink/adhesive well and generally give good results.

- Synthetics (like polyester, nylon) can be good but require specific settings because of heat and surface issues.

- Blends (cotton + poly, tri-blends) are a hybrid, good comfort + durability if chosen correctly.

- Surface Texture & Smoothness

- Smooth and even surfaces allow the adhesive powder and film to grip properly.

- Rough textures, heavy weave, big texture patterns can interfere. For example, one guide says: “fabrics with smooth and even textures yield better results”.

- Color & Fabric Base

- Light colours allow the design to pop easier; dark fabrics often need an under-white layer or extra powder for opacity.

- The fabric colour won’t change the physical bonding issue, but the visual outcome is impacted.

- Heat Tolerance / Shrink Behavior

- Since DTF uses heat-pressing, the fabric must withstand the defined temperature, pressure and time without shrinking, melting or warping.

- If it shrinks after pressing, the design can distort. One source flags: “the heat resistance and adhesion properties matter”.

- Stretch & Recovery / Movement

- Fabrics that stretch a lot (high spandex/lycra content) can make the print crack when worn or washed.

- The print needs to flex a little with the fabric or be on a fabric that doesn’t stretch too wildly.

- Care & Durability Requirements

- How you’ll wash, wear and treat the garment matters. Even perfect prints on perfect fabric will fail if you wash badly. We’ll cover care later.

- The fabric’s long-term behaviour (does it pill, fade, shrink) impacts the look of the print.

When you check all these boxes, you’re putting yourself in the “likely to succeed” zone rather than “hope it works” zone.

Fabrics That Are Solid Choices for DTF Transfers

Fabrics That Are Solid Choices for DTF Transfers

Let’s go through the fabrics that we recommend you go with, especially since you’re targeting young/teen/urban wear and want strong results.

1. 100% Cotton

Why it works:

- Cotton absorbs ink and adhesive well- good bonds and vivid print. One guide says: “Cotton offers excellent ink absorption and detail clarity.”

- It’s comfortable, breathable, cool to wear- important for younger audiences.

- Very common in casual custom tees, hoodies.

Tips & caveats:

- Choose pre-shrunken cotton when possible, or at least fabrics that have minimal shrink. Because if the fabric shrinks after printing, you’ll risk print distortion. One source mentions shrinkage as a con for cotton.

- Pay attention to your heat press settings: cotton can take typical settings, but you don’t want to go overboard.

- On dark 100% cotton, you may still need white underbase or extra adhesive/powder to allow colours to pop.

Best for: Standard graphic tees, merch drops, everyday wear.

2. 100% Polyester

Why it works:

- Polyester may surprise you: “Polyester prints are bright and vivid… widely used in sportswear” according to several sources.

- It resists shrinking, retains shape, handles active wear, and the smooth finish can help prints look sharp.

- Good for hoodies, sports-style gear, custom gear with movement.

Tips & caveats:

- Because it’s synthetic, you may need to lower your heat/pressure/time a bit compared to cotton. One guide states specific settings differ. Ensure the polyester is a smooth finish, not heavily textured or coated (coating can block adhesion).

- The “hand feel” (how it feels) of the print on polyester might differ (may feel less soft than cotton prints) — but good DTF films can close the gap.

Best for: Team wear, sports jerseys, premium hoodies, custom activewear.

Let’s go through the fabrics that we recommend you go with, especially since you’re targeting young/teen/urban wear and want strong results.

1. 100% Cotton

Why it works:

- Cotton absorbs ink and adhesive well- good bonds and vivid print. One guide says: “Cotton offers excellent ink absorption and detail clarity.”

- It’s comfortable, breathable, cool to wear- important for younger audiences.

- Very common in casual custom tees, hoodies.

Tips & caveats:

- Choose pre-shrunken cotton when possible, or at least fabrics that have minimal shrink. Because if the fabric shrinks after printing, you’ll risk print distortion. One source mentions shrinkage as a con for cotton.

- Pay attention to your heat press settings: cotton can take typical settings, but you don’t want to go overboard.

- On dark 100% cotton, you may still need white underbase or extra adhesive/powder to allow colours to pop.

Best for: Standard graphic tees, merch drops, everyday wear.

2. 100% Polyester

Why it works:

- Polyester may surprise you: “Polyester prints are bright and vivid… widely used in sportswear” according to several sources.

- It resists shrinking, retains shape, handles active wear, and the smooth finish can help prints look sharp.

- Good for hoodies, sports-style gear, custom gear with movement.

Tips & caveats:

- Because it’s synthetic, you may need to lower your heat/pressure/time a bit compared to cotton. One guide states specific settings differ. Ensure the polyester is a smooth finish, not heavily textured or coated (coating can block adhesion).

- The “hand feel” (how it feels) of the print on polyester might differ (may feel less soft than cotton prints) — but good DTF films can close the gap.

Best for: Team wear, sports jerseys, premium hoodies, custom activewear.

3. Cotton-Polyester Blends (50/50 etc)

Why they’re a smart middle ground:

- Combine the comfort of cotton + durability of poly.

- Many custom clothing lines and merch runs favour blends because they minimise shrink, offer good print characteristics and cost less than specialty fabrics.

- Guides say: “blended fabrics offer the best of both worlds… DTF prints adhere well”.

Tips & caveats:

- Always check the blend ratio: something like 60% poly / 40% cotton might behave differently than 50/50.

- With blends, you still want to test one piece to confirm settings (heat/pressure/time) because the poly portion might react differently.

- For mass-merch, these are often the safe bet: a bit better durability than pure cotton, good cost efficiency.

Best for: Brand merch, groups, casual wear where you’ll print many pieces but still want decent quality.

4. Tri-Blends (Cotton / Polyester / Rayon)

Why you might pick it:

- Tri-blends are very popular for boutique style, “soft touch” tees. They drape well, feel lightweight, ideal for trend-following teens.

- One article says: “Tri-blends offer a unique texture and feel while still maintaining good printability.”

Tips & caveats:

- Because of the rayon (and extra fibres), the adhesive and print bonding may be slightly trickier. Some adhesion issues or durability differences may show. One source warns “rayon content can sometimes affect adhesion and durability.”

- Definitely test: stretch, wash, wear. Make sure the print holds up.

- For premium drops, this is a nice fabric, but it might cost more or require more care.

Best for: Boutique tees, fashion-y merch, limited edition drops where you want a premium feel.

5. Nylon (With Proper Treatment)

Why you’d go here:

- If you’re customizing outerwear, bags, backpacks or something non-tee, nylon is useful: lightweight, durable, smooth surface. Some DTF guides list it.

Tips & caveats:

- Nylon (especially if coated or used in outdoor gear) may not behave like cotton or poly: heat sensitivity, bonding issues, melting if settings are too hot.

- You’ll often need specific treatment: pre-pressing, correct adhesive powder, cold peel vs hot peel, lower temperatures.

- Because it’s less common for basic apparel prints, you might want to limit quantities or test small batches first.

Best for: Outerwear, accessories, backpacks, custom gear beyond just tees.

Fabrics to Use With Caution or Avoid for DTF

Even though DTF technology has come a long way and is more flexible than older print methods, there are fabrics that cause more trouble and are better avoided unless you’re experienced or testing heavily.

Here are fabrics you should proceed very cautiously with:

- Silk & Satin,slippery surfaces, delicate fibres, heat sensitivity. One source lists silk as one to be careful with.

- 100% Rayon – although soft and great feeling, the fibre can warp under heat and affect adhesion. Many guides mark it as risky.

- Heavily Textured Fabrics (e.g., corduroy, heavy wool, velvet), print might look uneven because the surface isn’t smooth.

- Water-proof or Coated Fabrics, the coating may repel ink/adhesive or heat may damage. One article states that coated fabrics block adhesion.

- High Stretch (High Spandex/Lycra Blends), if the fabric stretches a lot, the design may crack or distort when worn/washing.

- Leather / Suede (without proper treatment), some DTF articles say leather can work if treated, but it’s not straightforward.

Bottom line: If you’re just starting or doing a typical custom tee run, stick to the fabrics we listed earlier (cotton, poly, blends). Once you’re comfortable and have tested your process, you can explore the ‘caution zone’.

Care & Durability: How to Make Your Print Last

You nailed the right fabric + used a good DTF transfer supplier, but next you must handle the post-print process right so your gear stays fresh. The audience (teens and young adults) will wash frequently, throw items in quick cycles, and expect the gear to still look fire after months of wear.

Here are practical care tips (adapted for your audience)- because you want your custom tee to survive the squad, the laundry pile and still look good.

Printed Garment Care Checklist

- Turn it inside out before tossing in the wash- this minimises abrasion on the print.

- Wash in cold water, gentle cycle. Hot water can break down adhesive, fade colours, shrink fabric.

- Use a mild detergent, no bleach or harsh fabric softeners around the design area.

- Air-dry or tumble low. High heat in the dryer can damage both the fabric and the transferred film.

- When ironing, avoid direct contact with the printed area. Either iron inside out or use a cloth barrier between print and iron.

- If you’re doing a new print run: after pressing, allow the garment to cure (let the adhesive settle) before first wash or first wear.

- Store your printed garments properly- don’t fold heavily across the print for extended time, or hang where the print gets direct sun for long periods.

You’ll find that many custom printing guides emphasise these steps.

Real-World Scenario: How to Choose Fabric for Your Next Drop

Let’s put this into action with an example. Say you’re planning a custom tee drop for your brand, aimed at teens and young adults, for summer. You want something that looks good, feels comfortable, and stays fresh after multiple wears.

Here’s how you might think through the fabric choice:

- Goal: Casual, everyday wear tee, graphic design, vibrant colours.

- Audience: Teens/young adults who wash frequently, wear it to class, hang out in it, expect decent durability.

- Decision: 100% cotton or a 50/50 cotton-poly blend.

- If budget matters and you want max comfort- 100% cotton (pre‐shrunk).

- If you want longer durability, less shrink, fewer rejects- choose the 50/50 blend.

- Settings/Process: Use DTF film + powder, press with appropriate settings for that fabric (verify with supplier). After printing, allow proper cure, sample wash test.

- Care Instructions: Include care instructions with the garment (turn inside out, cold wash, air dry/low heat). This can help your customers take better care and keep your gear looking premium.

- Avoid: It would not make sense (for this drop) to pick tri-blend (premium cost) or nylon (outerwear) or a high stretch fabric that’s misaligned with the goal.

By thinking this way, you align the fabric, print method, audience and care instructions.

FAQ's

Q: Can I use DTF on dark fabrics?

Yes, one of the advantages of DTF is that you can print on dark or coloured fabrics because you can include white under-base in the transfer. Just ensure the fabric surface is smooth and your film/adhesive is compatible.

Cheaper blanks often mean lower quality fabric: high shrink, uneven surface, cheaper fibres. That can lead to print issues. Always test a run, especially if you’re scaling up.

Q: How many washes can a DTF print on a good fabric survive?

While there’s no exact number (because it depends on print quality, fabric, wash conditions), with a good fabric + correct process + good care, prints can last many washes and still look good. One guide mentions DTF printed patterns “will not be worn out easily” when done correctly.

Q: Does fabric weight matter?

Yes, heavier garments (300 gsm hoodies, etc) often have different heating/pressing dynamics (they retain heat, may compress differently). While the fibre content matters more, weight/structure do affect how the heat press works. So test heavier blanks if you’re switching from standard tees.

Q: Even within cotton, are there differences?

Absolutely. Ring-spun cotton, combed cotton, single-jersey vs interlock knit, all impact surface smoothness, print clarity and hand-feel. A Reddit user in the screen-printing community noted:

“In my experience, ringspun cotton like the Next Level 3600 can actually handle DTF pretty well if you cure and press it correctly.”

So yes, the quality of cotton matters.